Introduction

Every IoT ecosystem is judged by the quality of its data. It doesn’t matter if you have the best cloud dashboards or the most advanced analytics platform — if your sensors are inaccurate or poorly calibrated, “garbage in = garbage out.”

Sensor calibration is the art and science of aligning sensor outputs with reality. Whether measuring temperature, humidity, motion, pressure, or air quality, calibration ensures values are accurate, consistent, and trustworthy.

At Curiosity Tech Nagpur IoT Workshops, I often remind learners: “An IoT system fails not because the data wasn’t collected, but because the data wasn’t calibrated correctly.” In professional factories, hospitals, or cities, minutes of wrong readings can mean lost product batches, misdiagnosis, or security failures.

What is Calibration in IoT Sensors?

Calibration is the process of comparing sensor outputs with a reference standard and adjusting (in software or hardware) to reduce measurement error.

- Uncalibrated Sensor: Reads “25°C” when reference thermometer says 24.2°C.

- Calibrated Sensor: Adjusted to display 24.2°C ± 0.1°C, ensuring accuracy.

Why Sensor Calibration Matters in IoT

- Accuracy: Without calibration, analytics are flawed.

- Consistency: Ensures values are trusted across multiple devices.

- Compliance: Industries (pharma, food, healthcare) follow ISO standards requiring calibrated instrumentation.

- Reliability at Scale: Thousands of IoT devices need uniform performance.

- Edge Integration: Many calibration offsets get applied at firmware level.

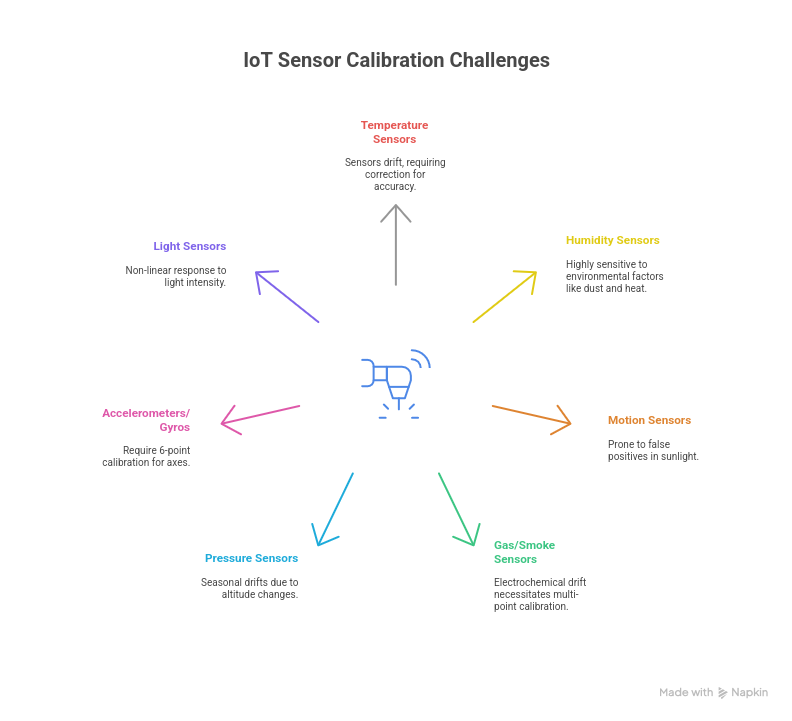

Common IoT Sensors & Their Calibration Needs

| Sensor Type | Typical IoT Use Case | Calibration Concern |

| Temperature (DHT11, DS18B20) | Agriculture, homes, factories | Sensor drift ±2°C – needs correction |

| Humidity (DHT22, SHT31) | Warehousing/storage monitoring | High sensitivity to dust/heat |

| PIR Motion Sensor | Security IoT | False positives in sunlight |

| Gas/Smoke Sensors (MQ-2, MQ-135) | Air quality monitoring | Electrochemical drift, requires multi-point calibration |

| Pressure/Barometric Sensors | Smart weather platforms | Drifts seasonally with altitude |

| Accelerometers/Gyros | Wearables, robotics | Require 6-point calibration for axes |

| Light Sensors (LDRs, photodiodes) | Smart lighting | Non-linear response to lux |

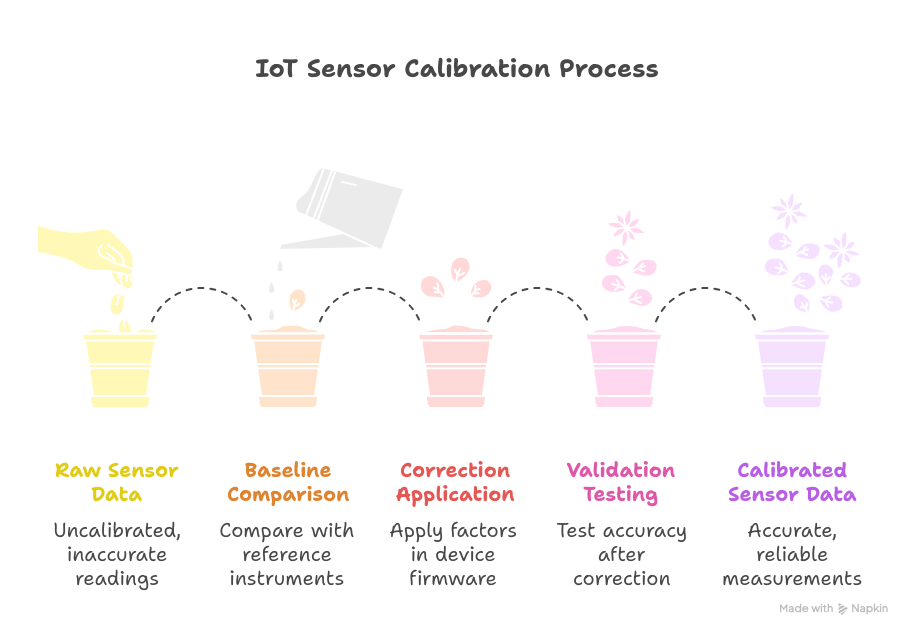

Step-by-Step Sensor Calibration Procedure (Lab Manual Style)

1: Establish a Reference Standard

- Use a high-accuracy instrument (e.g., mercury thermometer for temperature sensor, precision anemometer for wind sensor).

- References should comply with ISO/NIST standards in industrial setups.

2: Collect Baseline Data

- Set up the sensor in a controlled environment.

- Take multiple readings at known reference values.

3: Identify Errors

- Compare sensor values with reference values.

- Errors may be:

- Offset Error: Reading is consistently higher/lower.

- Gain Error: Wrong slope/scale of readings.

- Non-linearity: Errors vary across measurement range.

4: Apply Corrections

- Firmware Calibration: Add correction coefficients in code.

- Software Calibration: Dashboard applies correction formulas dynamically.

- Hardware Calibration: Adjust resistors, trim pots (older methods).

5: Validate Accuracy

- Re-test on fresh reference samples to check improved accuracy.

6: Document Calibration

- Record dates, methods, offsets applied.

- Industrial sectors require regular calibration reports as compliance proof.

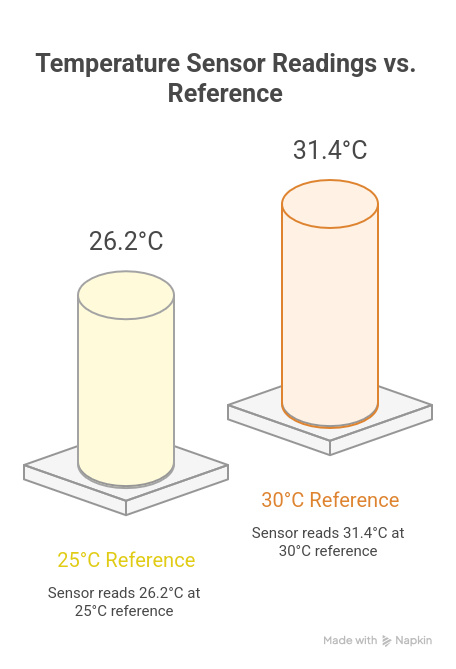

Example: Calibrating a DHT22 Temperature Sensor

Setup:

- DHT22 sensor connected to ESP32.

- Reference thermometer: Fluke calibrated probe.

Reference vs. Sensor:

- At 25°C reference → sensor = 26.2°C.

- At 30°C reference → sensor = 31.4°C.

Error: Consistent +1.2°C offset.

Correction Code (ESP32 in Arduino IDE): cpp

float corrected_temperature = raw_temp – 1.2;

Result: After correction, readings aligned within ±0.1°C against reference.

This is taught firsthand at CuriosityTech labs during IoT calibration bootcamps.

Error Analysis in IoT Sensors

Common errors include:

- Offset/Zero Error – constant bias in measurements.

- Drift – sensor accuracy degrades over months of use.

- Hysteresis – sensor shows different readings while moving up vs. down (common in humidity sensors).

- Noise Sensitivity – interference causes jitter (seen in analog sensors near motors).

Example Table of Error Impact

| Sensor Type | Without Calibration Error | With Calibration |

| Temperature Node | ±2.0°C (bad for pharma) | ±0.2°C (acceptable) |

| Humidity Sensor | ±7% RH (storage doors open) | ±1.5% RH |

| Gas MQ-135 | ±20% in CO₂ ppm | ±4% after recalibration |

Industrial Case Studies

Case Study 1: Food Storage Cold Chain

- Problem: IoT temperature loggers in trucks gave false +3°C deviation.

- Solution: Calibration against certified probes.

- Result: Reduced food spoilage incidents by 18%, regulatory compliance achieved.

2: Smart Agriculture Soil Monitoring

- Farmers at CuriosityTech nagpur pilot farm noticed soil data varied across devices.

- Calibration with moisture oven-dry testing was used as baseline.

- Result: Trend consistency across all 50 deployed soil IoT nodes, leading to accurate irrigation automation.

3: Wearable Fitness Devices

- Gyroscope drift caused inaccurate calorie count.

- Apple & Fitbit integrate continuous auto-calibration with user motion over time.

Challenges in Sensor Calibration for IoT

- Scale Issue: Calibrating thousands of devices at once.

- Environment Factors: Field calibration affected by dust, humidity, external noise.

- Maintenance: Sensors drift; recalibration cycles must be automated.

- Cost vs Accuracy: Over-calibration increases costs in low-cost IoT devices.

Emerging Trends in Calibration (2025)

- Auto-Calibration Algorithms – Devices continuously correct themselves using reference “anchors” in networks.

- AI-Powered Drift Detection – Machine learning predicts when a sensor has drifted out of tolerance.

- Blockchain Calibration Logs – Calibration records stored on blockchain for compliance in pharma/logistics sectors.

- Factory Pre-Calibration – Industry demand for pre-calibrated sensors reduces time to deploy.

Curiosity Tech IoT Lab Activity – Calibration Session

- Setup: DHT, MQ-series gas sensors, PIR sensors deployed around Nagpur IoT Park.

- Students provided with reference instruments.

- Task: Compare IoT device data with reference, apply correction factors in firmware, test again.

- Outcome: Learners fully understood calibration as an engineering responsibility, not just coding.

Conclusion

Sensor calibration is the foundation of IoT trust. Without accuracy, IoT deployments lose integrity, leading to faulty automation, wrong analytics, and even safety hazards.

For IoT engineers in 2025, calibration must be considered as routine as writing firmware. In fact, factories, healthcare setups, and farms thrive only when their IoT devices are trusted for accuracy, consistency, and compliance. Without proper calibration, however, even the most advanced systems can deliver unreliable results.

Therefore, sensor calibration is not just a technical step but a critical responsibility. Moreover, it ensures long-term device performance and regulatory compliance across industries. As a result, organizations can confidently rely on their IoT infrastructure for data-driven decisions.

That’s why Curiosity Tech in Nagpur ensures sensor calibration training is embedded into every workshop. Not only do they teach IoT enthusiasts how to connect devices, but they also emphasize making devices accurate, reliable, and industry-ready. Ultimately, this approach helps build professionals who understand that precision is just as important as innovation.