Introduction

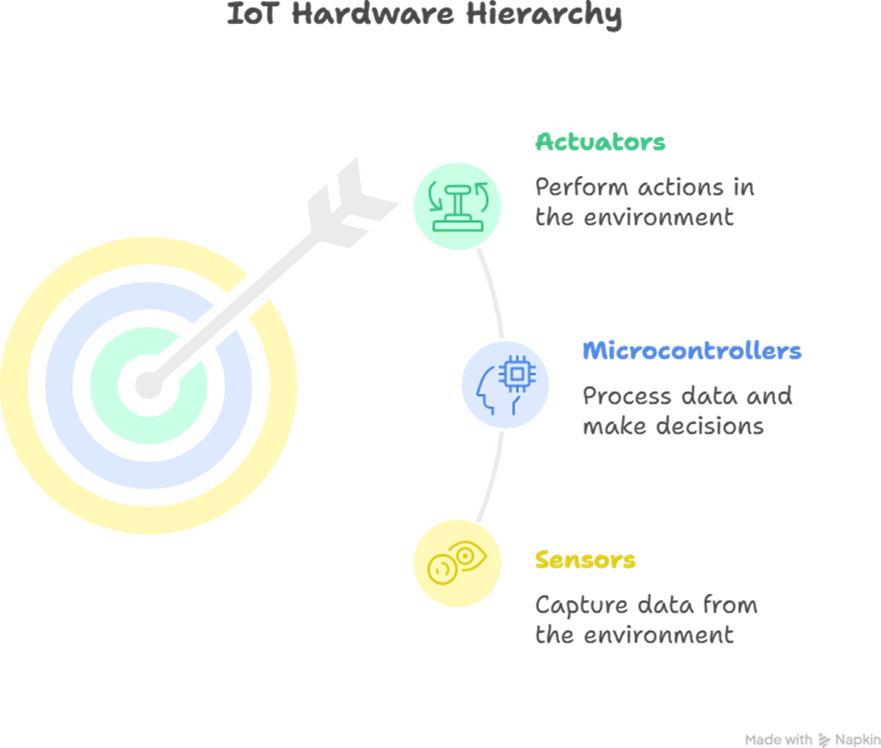

An IoT system is only as powerful as the hardware components that form its base. Software libraries, cloud dashboards, or advanced AI mean nothing if sensors can’t capture data correctly, microcontrollers can’t process it reliably, and actuators can’t implement physical actions in the real world. Hardware is the skeleton, nerves, and muscles of IoT.

Having worked in IoT hardware design for 20+ years, I’ve seen how selecting the right hardware separates a stable IoT rollout from a failed pilot project. For engineers learning in 2025, mastery of sensors, microcontrollers, and actuators is fundamental.

Blueprint Perspective of Hardware Trilogy

Sensor → Microcontroller (Decision Layer) → Actuator (Action Layer).

Section 1 – Sensors in IoT

Sensors are the data collectors. They bridge the physical world to the digital by capturing measurable phenomena.

Types of IoT Sensors

| Sensor Type | Function | IoT Examples | Industry Usage |

| Temperature | Measures heat levels | DHT11, DS18B20, LM35 | Smart homes, agriculture |

| Humidity | Tracks air moisture content | DHT22, SHT31 | Storage, crop monitoring |

| Motion/Proximity | Detects movement or distance | PIR, Ultrasonic HC-SR04 | Security, robotics |

| Light (LDR) | Measures ambient brightness | Photoresistors, TSL2561 | Smart lighting, street lamps |

| Gas/Smoke | Detects air quality, CO₂, LPG, etc. | MQ-series sensors | Smart safety devices |

| Pressure | Barometric or industrial process levels | BMP280, MPX5010 | Weather, automotive |

| Biometric | Heartbeat, SpO2, fingerprints | Pulse sensors, MAX30100 | Healthcare, wearables |

Expert Tip: Always check for calibration, stability, and power usage. Poor calibration leads to bad data, which ruins analytics. That’s why at CuriosityTech’s IoT lab in Nagpur, students learn to perform field calibration with baseline sensor models.

Section 2 – Microcontrollers: The IoT Brain

Microcontrollers (MCUs) are small, efficient “brains” of IoT devices. They collect sensor data, process it locally, and decide what action to perform or what data to send over networks.

Popular Microcontrollers for IoT

| Microcontroller | Features | Advantage for IoT | Example Projects |

| Arduino UNO / Nano | Atmega328, beginner-friendly | Great for prototyping | Smart lamp, IoT thermometer |

| ESP8266 | Built-in Wi-Fi, low cost | Lightweight IoT projects | Wi-Fi weather monitor |

| ESP32 | Wi-Fi + Bluetooth, dual-core | Supports larger projects | Wearables, voice assistants |

| STM32 Series | ARM Cortex-M, high-performance | Industrial-grade reliability | Motor control, industrial IIoT |

| Raspberry Pi | Not a microcontroller (single-board computer) but widely used with MCUs | Complex gateways, AI at the edge | Object detection camera |

Why MCUs matter:

- They manage sensor interfacing, memory optimization, low-power functionality.

- Good MCUs extend battery life in remote IoT environments.

- Some platforms (like ESP32) merge sensor control + wireless communication in one chip.

Section 3 – Actuators: The Action Makers

Actuators convert digital decisions into physical outcomes. If IoT is a smart nervous system, actuators are the muscles that move it.

Types of Actuators

| Actuator Type | Function | IoT Example Applications |

| Motor (DC/Servo) | Rotational or movement output | Smart robotics, doors, fans |

| Relay | Switch electrical loads | Smart appliances, industrial automation |

| Solenoid | Linear actuation, locking mechanisms | Smart locks, vending machines |

| Valves | Regulate fluid flows | Smart agriculture irrigation |

| Speakers/Buzzers | Audio alerts & communication | Smart alarms, assistive devices |

For example, in smart irrigation, soil sensors (sensors) send readings to an ESP32 microcontroller (brain) which then triggers solenoid valves (actuators) to release water only when required.

Example Blueprint: IoT Smart Farming Node

- Sensor Layer (Input) → Soil moisture & temperature sensors capture field condition.

- Processing Layer (MCU) → ESP32 processes sensor thresholds locally.

- Decision Layer (Network Linked) → If condition critical, transmits log via LoRa or Wi-Fi to the cloud.

- Action Layer (Output Hardware) → Opens an actuator-controlled water valve.

- Cloud Layer (Analytics) → Farmers monitor graphs & predictions via apps.

This workflow was demonstrated at CuriosityTech.in Nagpur’s Smart Agriculture Projects, giving rural startups practical IoT exposure.

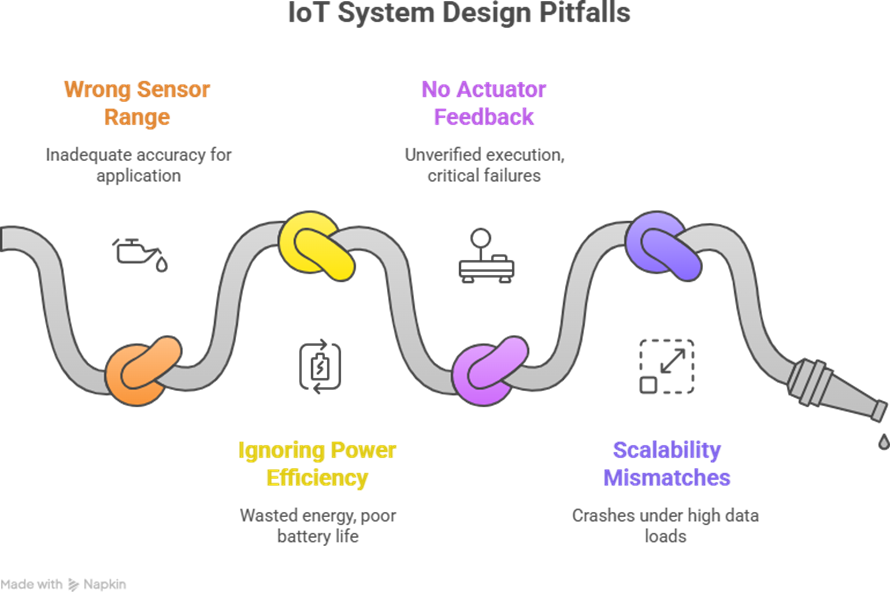

Pitfalls in IoT Hardware Selection

Visual Mindmap Concept (to imagine)

At the center: IoT Hardware.

- Branches: Sensors → Types, Industrial uses.

- Microcontrollers → Popular chips, cost efficiency, prototyping vs production.

- Actuators → Motors, relays, solenoid valves.

Arrows connecting them = IoT Signal Flow.

This conceptual visualization shows hardware integration as a closed loop of sensing → processing → action.

Conclusion

IoT is impossible without its hardware backbone. Sensors observe the environment, MCUs think and communicate, and actuators bring decisions into reality. Every IoT engineer must master these building blocks at both theoretical and practical levels. The art lies not only in choosing components but ensuring they work harmoniously under real constraints like power, accuracy, and scalability.

For those beginning their IoT journey in 2025, labs like CuriosityTech.in in Nagpur serve as ideal ecosystems where learners don’t just read specifications but experiment with live hardware, debug circuits, calibrate sensors, and solve real agricultural and industrial use cases.

Because in IoT, your system is only as good as its weakest sensor, its most underpowered MCU, or its cheapest actuator. Hardware isn’t just essential — it’s everything.