Introduction

Robots are complex systems made up of multiple components working together seamlessly. Understanding these components is the foundation for any robotics engineer. Every robot, from a simple line-following bot to an industrial robotic arm, relies on sensors to perceive, actuators to act, and controllers to coordinate these actions.

At CuriosityTech.in, learners get practical exposure to these components through hands-on tutorials and real-life projects, helping beginners convert theoretical knowledge into functional systems.

1. Sensors: The Robot’s Sense Organs

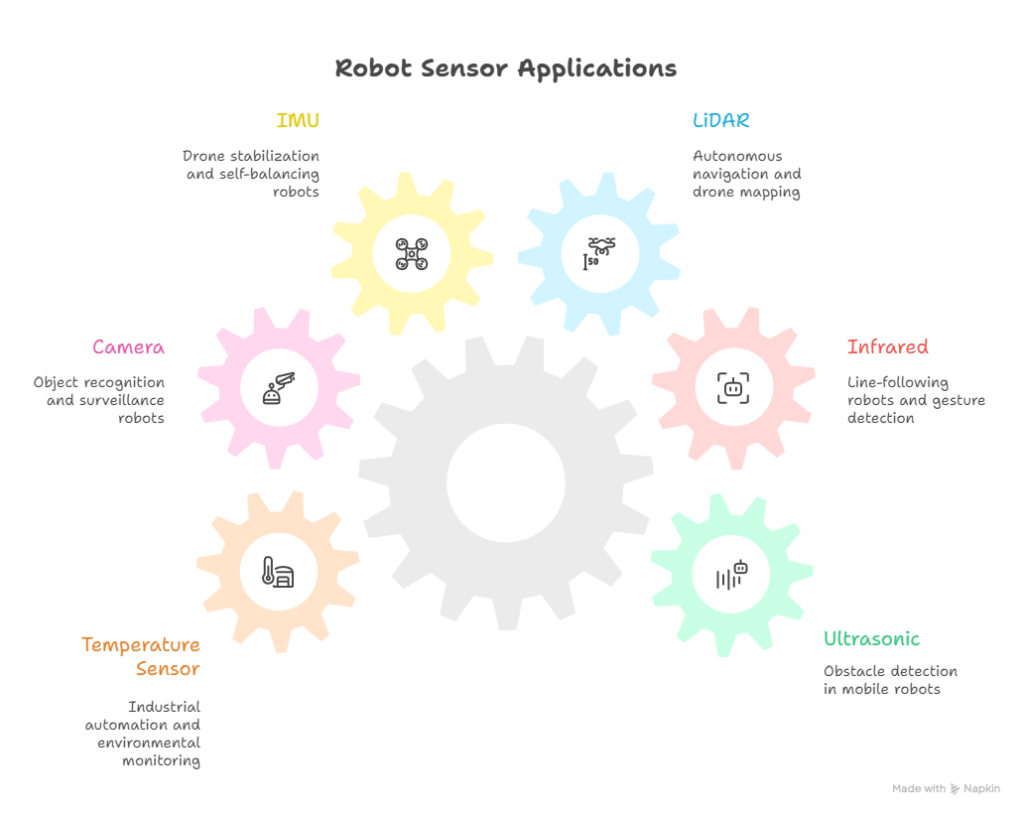

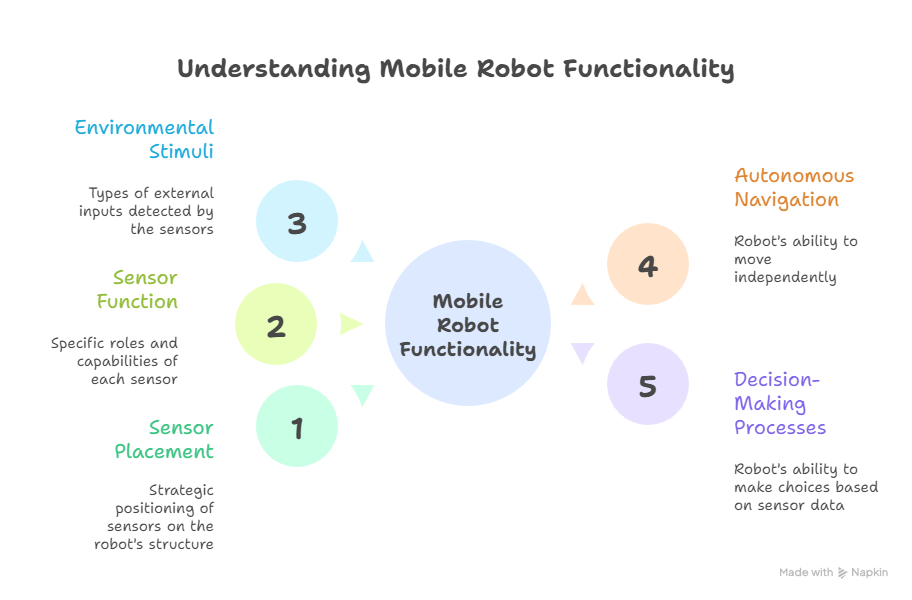

Sensors allow robots to perceive the environment. They provide critical data that informs decisions, navigation, and interaction.

| Sensor Type | Function | Example Application |

| Ultrasonic | Measures distance using sound waves | Obstacle detection in mobile robots |

| Infrared (IR) | Detects heat or proximity | Line-following robots, gesture detection |

| LiDAR | Creates high-resolution 3D maps | Autonomous navigation, drones |

| IMU (Gyroscope/Accel) | Measures orientation, angular velocity, acceleration | Drone stabilization, self- balancing robots |

| Camera / Machine Vision | Captures images and videos for analysis | Object recognition, surveillance robots |

| Temperature Sensor | Measures heat levels | Industrial automation, environmental monitoring |

Infographic Idea: A schematic of a mobile robot showing sensors at various locations, highlighting which sense what.

Practical Tip: Beginners can integrate ultrasonic and IR sensors with Arduino to make robots detect obstacles and follow lines.

2. Actuators: How Robots Move

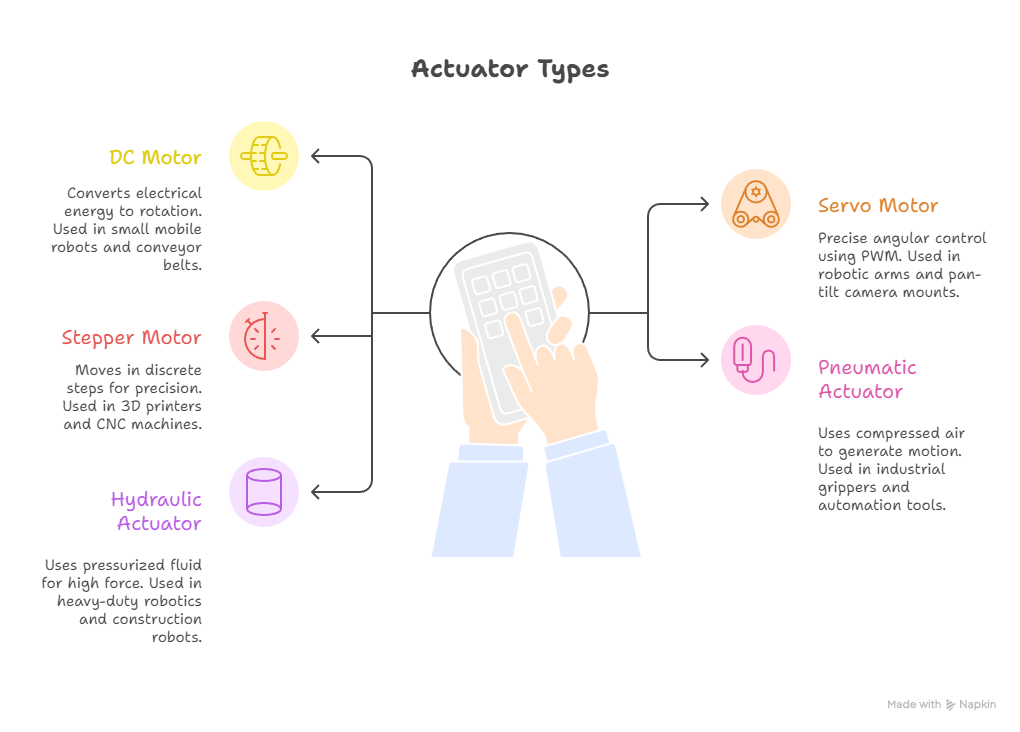

Actuators are the muscles of a robot. They convert electrical signals into physical motion. The type of actuator determines the movement style and precision of the robot.

Types of Actuators:-

| Actuator Type | Principle | Example Application |

| DC Motor | Converts electrical energy to rotation | Small mobile robots, conveyor belts |

| Servo Motor | Precise angular control using PWM | Robotic arms, pan-tilt camera mounts |

| Stepper Motor | Moves in discrete steps for precision | 3D printers, CNC machines |

| Pneumatic Actuator | Uses compressed air to generate motion | Industrial grippers, automation tools |

| Hydraulic Actuator | Uses pressurized fluid for high force | Heavy-duty robotics, construction robots |

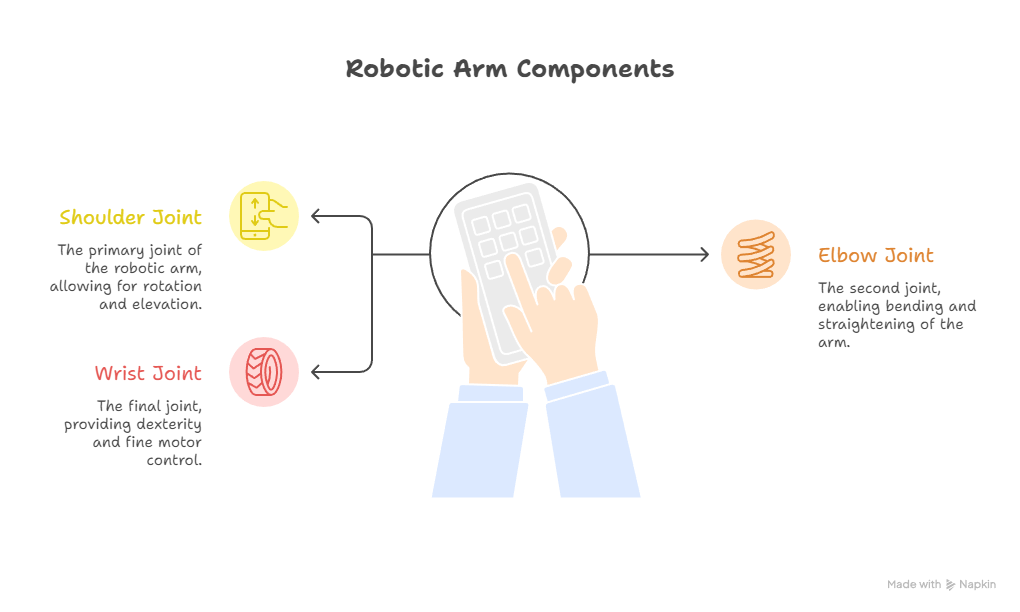

Diagram Idea: Illustration showing actuators moving a robotic arm with different joints labeled (shoulder, elbow, wrist) and the corresponding motor types.

3. Controllers: The Robot’s Brain

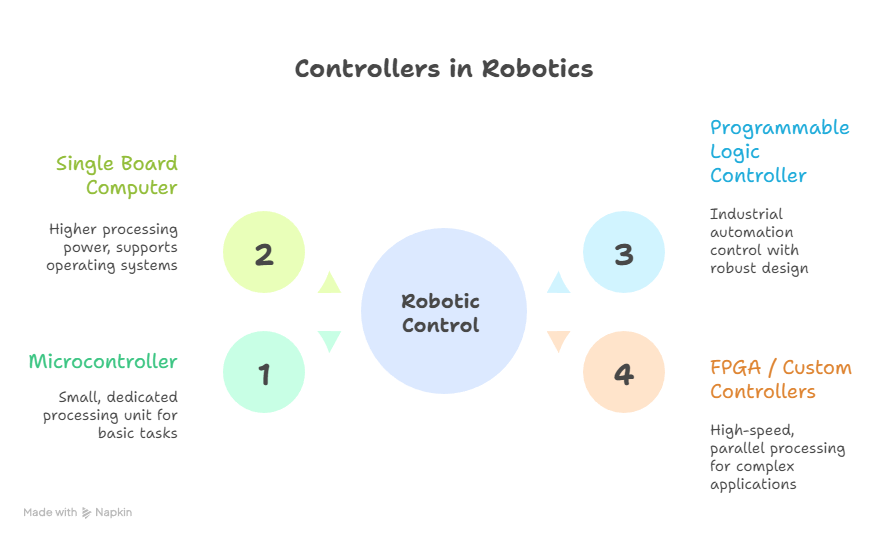

Controllers are embedded systems that process sensor data and command actuators. They are responsible for coordination, decision-making, and executing tasks.

Controller Types :-

| Controller Type | Description | Example Hardware |

| Microcontroller (MCU) | Small, dedicated processing unit | Arduino Uno, STM32 |

| Single Board Computer (SBC) | Higher processing, supports OS | Raspberry Pi, NVIDIA Jetson Nano |

| Programmable Logic Controller (PLC) | Industrial automation control | Siemens, Allen-Bradley |

| FPGA / Custom Controllers | High-speed, parallel processing for complex tasks | Autonomous drones, high-frequency robots |

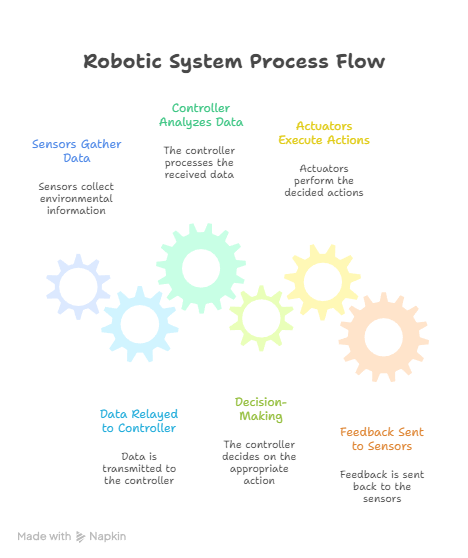

Hierarchical Diagram Idea: Sensors → Controller → Decision-Making → Actuators → Feedback to Sensors

Description: Shows closed-loop control where sensors provide data, the controller decides, and actuators execute, forming a continuous loop.

4. Integration of Components

A robot’s functionality depends on how effectively sensors, actuators, and controllers work together:

- Perception (Sensors): Detects environment or internal states.

- Processing (Controller): Analyzes sensor data, plans actions, and generates commands.

- Action (Actuators): Executes commands to interact with the environment.

Example Project:

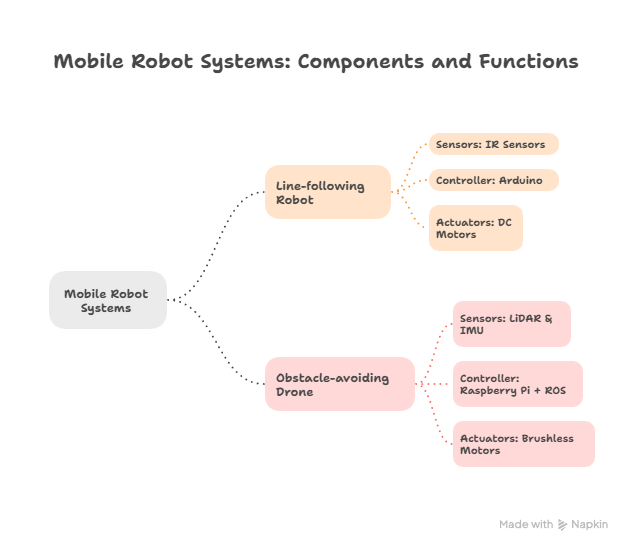

- Line-following robot:

- Sensors: IR sensors detect the path.

- Controller: Arduino processes sensor input and decides wheel motion.

- Actuators: DC motors move the robot along the line.

- Obstacle-avoiding drone:

- Sensors: LiDAR & IMU for distance and orientation.

- Controller: Raspberry Pi + ROS computes path adjustments.

- Actuators: Brushless motors adjust propellers to navigate safely.

At CuriosityTech.in, you can find tutorials for these projects with step-by-step sensor integration and controller programming, making the learning process smooth and engaging.

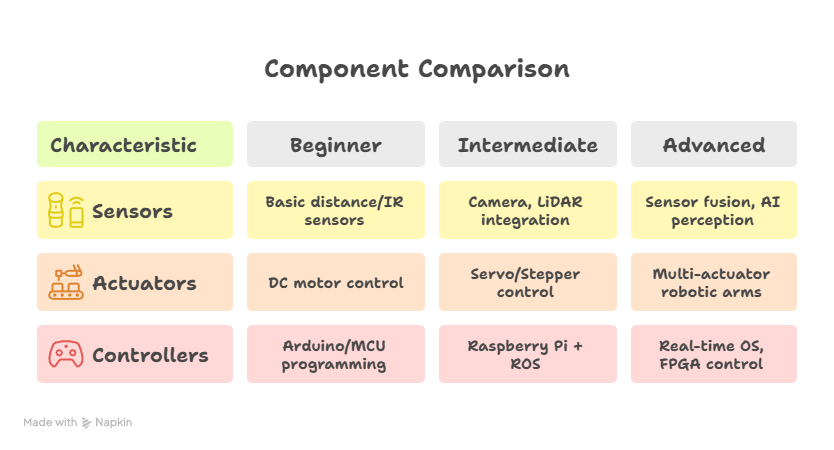

5. Skills to Master Component Integration

- Understanding sensor specifications: range, accuracy, latency.

- Actuator control and motor tuning (PID, PWM).

- Real-time processing with microcontrollers or SBCs.

- System-level debugging: ensuring smooth data flow from sensors to actuators.

- Simulation tools: Gazebo, V-REP to test robots virtually before hardware implementation.

Table: Component Mastery Roadmap

Conclusion

Understanding sensors, actuators, and controllers is the backbone of robotics engineering. Mastering each component individually and learning how to integrate them effectively allows engineers to design, build, and operate complex robots.

Resources at CuriosityTech.in offer practical guidance for experimenting with all these components, providing learners a hands-on approach to becoming skilled robotics engineers.