Introduction

Industrial robotics has revolutionized manufacturing and automation by enhancing efficiency, precision, and safety. Robots in industrial settings perform tasks ranging from assembly, welding, packaging, inspection, and material handling. Understanding industrial robotics is crucial for engineers seeking careers in automation, smart factories, and advanced manufacturing systems.

At CuriosityTech.in, learners gain insights into real-world industrial applications, automation workflows, and project-based learning for robotics integration.

1. What is Industrial Robotics?

Industrial robotics refers to the use of robots in industrial settings to automate tasks traditionally performed by humans. These robots are programmed, repetitive, and precise, designed for high productivity, safety, and scalability.

Characteristics of Industrial Robots:

- Programmable and reconfigurable.

- Designed for repetitive, high-speed tasks.

- Equipped with actuators, sensors, and controllers for precision.

- Can operate in hazardous environments where humans may be at risk.

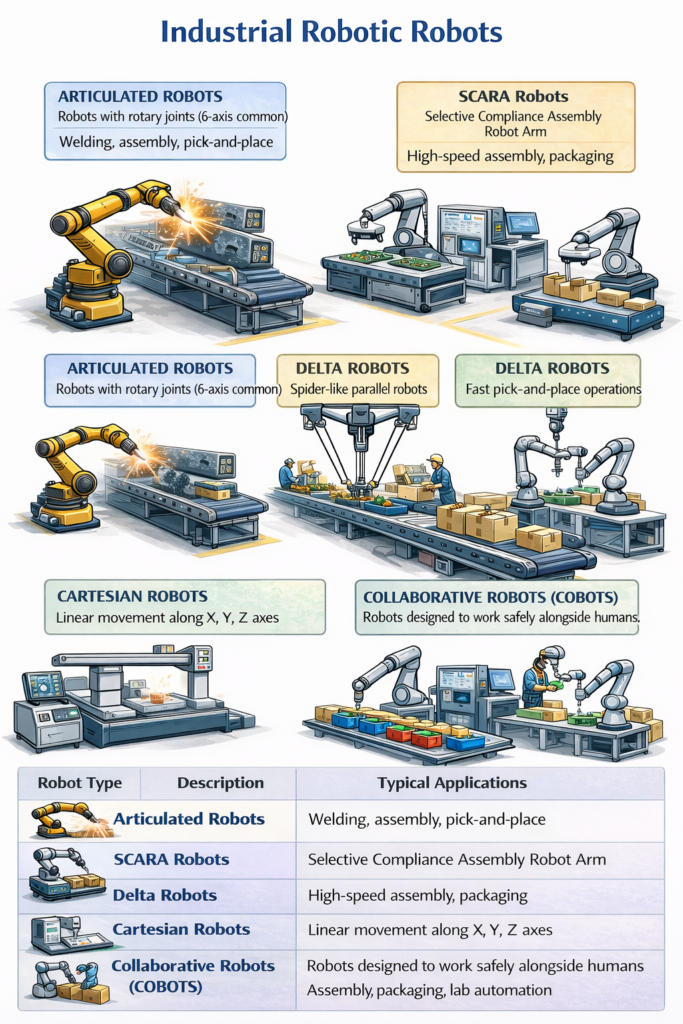

2. Types of Industrial Robots

| Robot Type | Description | Typical Applications |

| Articulated Robots | Robots with rotary joints (6-axis common) | Welding, assembly, pick-and-place |

| SCARA Robots | Selective Compliance Assembly Robot Arm | High-speed assembly, packaging |

| Delta Robots | Spider-like parallel robots | Fast pick-and-place operations |

| Cartesian Robots | Linear movement along X, Y, Z axes | CNC machines, 3D printing, material handling |

| Collaborative Robots (Cobots) | Robots designed to work safely alongside humans | Assembly, packaging, lab automation |

Diagram Idea: Illustration showing each robot type performing its specific task on a factory floor.

3. Key Applications in Manufacturing & Automation

- Assembly Line Automation :-

- Robots perform repetitive assembly tasks.

- Examples: Car manufacturing, electronics assembly.

- Benefits: High accuracy, reduced labor costs.

- Material Handling :-

- Transporting, stacking, or organizing materials.

- Examples: Palletizing in warehouses, moving heavy parts.

- Benefits: Reduces human effort and workplace injuries.

- Welding and Painting :-

- Robots perform consistent welds and uniform painting.

- Examples: Automotive industry for spot welding car frames.

- Benefits: Consistent quality, reduced defects.

- Quality Inspection :-

- Vision systems integrated with robots for real-time inspection.

- Examples: Checking product dimensions, surface defects.

- Benefits: Faster and more accurate than human inspection.

- Packaging and Palletizing :-

- Robots pack products and arrange them on pallets.

- Examples: Food and beverage, pharmaceuticals.

- Benefits: High throughput, precise placement.

4. Workflow of Industrial Robotic Automation

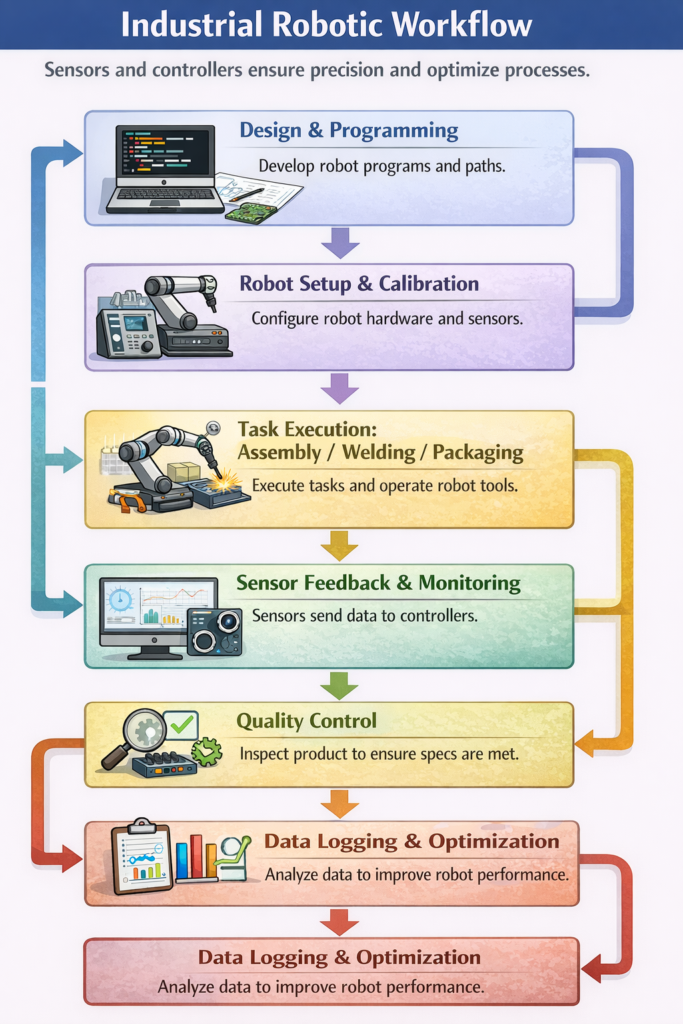

Flowchart Idea:

Description: Industrial robots follow programmed paths and processes. Sensor feedback ensures precision, while controllers optimize performance and minimize errors.

5. Sensors & Actuators in Industrial Robotics

- Sensors:

- Vision cameras for inspection.

- Force/torque sensors for assembly precision.

- Proximity sensors for safety and obstacle detection.

- Actuators:

- Servo motors for joint rotation.

- Pneumatic actuators for linear motion.

- Hydraulic actuators for high-load operations.

Table: Sensor & Actuator Roles in Industrial Robots

| Function | Sensor/Actuator | Purpose |

| Joint Control | Servo Motors | Precise rotation for arm movement |

| Linear Movement | Pneumatic/Hydraulic Actuator | Material handling, lifting heavy loads |

| Part Detection | Vision Sensor | Inspecting presence, defects, and orientation |

| Force Control | Torque Sensor | Ensuring proper assembly force |

| Safety | Proximity/Infrared Sensor | Human safety and obstacle detection |

6. Real-World Case Study: Automotive Assembly Line

Scenario: A car manufacturing plant integrating robotic systems.

Robotics Workflow:

- Body Assembly: Articulated robots perform welding.

- Painting: Automated painting robots ensure uniform coating.

- Inspection: Vision systems check welds and surface defects.

- Material Handling: SCARA and Cartesian robots transport components.

- Packaging & Logistics: Delta robots pack parts and organize pallets.

Outcome:

- Increased productivity by 40–50%.

- Reduced workplace injuries significantly.

- Consistent product quality with minimal defects.

Diagram Idea: Flowchart showing car assembly with robots at each stage.

7. Advantages of Industrial Robotics

- Increased Productivity: Operates continuously without fatigue.

- High Precision & Quality: Repeatable tasks with minimal errors.

- Cost Efficiency: Long-term reduction in labor costs.

- Safety: Handles hazardous tasks, reducing accidents.

- Scalability: Easily reprogrammed for new tasks or products.

8. Challenges and Considerations

- High Initial Investment: Purchasing and integrating robots is expensive.

- Maintenance & Downtime: Regular checks and updates required.

- Programming Complexity: Skilled engineers needed for programming and tuning.

- Integration with Human Workers: Safety protocols are critical when using cobots.

9. Tips for Learning Industrial Robotics

- Start with simulation platforms like ROS, Gazebo, or V-REP.

- Explore robot programming languages like RAPID (ABB), KRL (KUKA), or Python for ROS.

- Understand PLC integration with robotic systems.

- Study sensor-actuator feedback loops for precision tasks.

- Follow real-world case studies on factory automation projects for insights.

CuriosityTech.in provides detailed guides on industrial robot programming, sensor integration, and workflow optimization, allowing learners to gain practical exposure to automation systems.

Conclusion

Industrial robotics is a cornerstone of modern manufacturing and automation, providing efficiency, precision, and safety. By understanding robot types, sensors, actuators, and industrial workflows, engineers can design, implement, and optimize robotic solutions for real-world factories. Platforms like CuriosityTech.in offer tutorials, case studies, and hands-on simulations that bridge the gap between theoretical knowledge and industrial applications.