Introduction

Theory alone cannot make you a successful business analyst. What sets great analysts apart is their ability to roll up their sleeves, analyze real processes, identify inefficiencies, and suggest improvements.

This blog walks you through a hands-on case study where we analyze a business process, apply frameworks, and propose an improved version. At CuriosityTech (https://curiositytech.in), we encourage learners to apply theory through workshops, simulations, and real-world problem-solving. By the end of this exercise, you’ll understand how to conduct process analysis and propose feasible improvements step by step.

1. Selecting a Process to Analyze

For demonstration, let’s choose a Retail Store Order Fulfillment Process — a familiar scenario for both beginners and experienced BAs.

Current Steps:

- Customer places an order.

- Order is recorded manually in a ledger.

- Staff checks inventory physically.

- If available, staff calls supplier for restock confirmation.

- Delivery arranged manually

- Payment collected on delivery.

Problem: Time delays, errors in manual entry, poor visibility of inventory, and inconsistent customer experience.

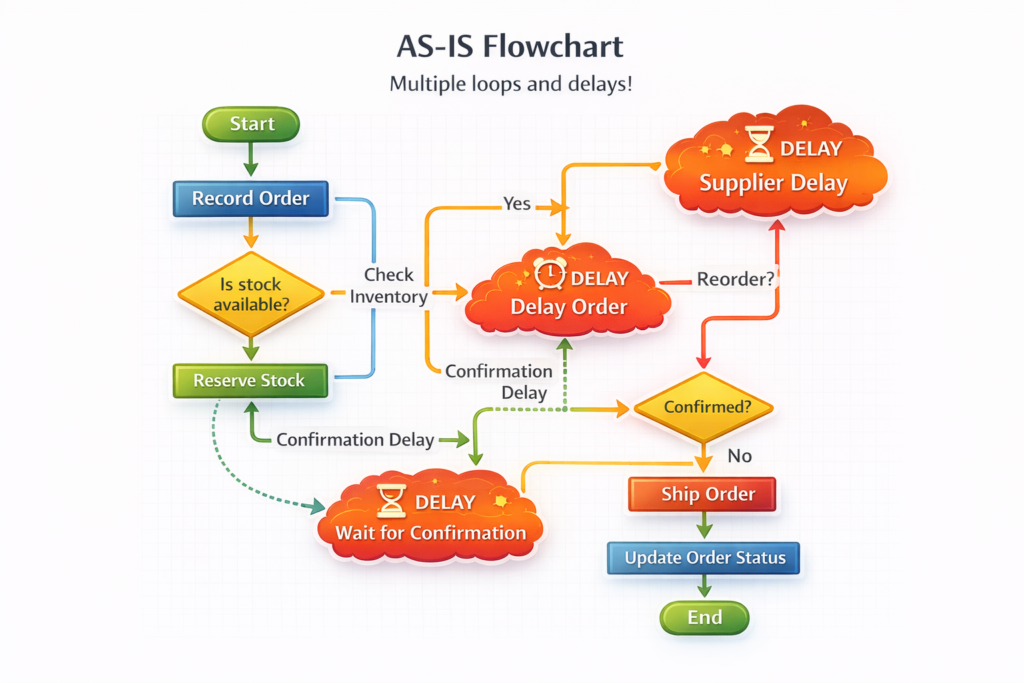

2. Analyzing the Current State (“As-Is” Process)

Tools & Techniques Used

- Flowcharting – To visualize the process.

- Observation – Shadowing staff performing tasks.

- Interviews – With store managers and delivery agents.

- Data Review – Looking at order turnaround times.

Diagram Description (As-Is Flowchart)

Imagine a flowchart with rectangles for tasks like “Record Order,” “Check Inventory,” and diamonds for decisions like “Is stock available?” showing multiple loops and delays.

3. Identifying Gaps & Inefficiencies

- Manual dependency: Order recording and inventory check slow the process.

- No integration: Inventory data is siloed from supplier and customer-facing systems.

- Payment bottleneck: COD delays financial reporting.

- Customer dissatisfaction: Delays cause canceled orders.

At CuriosityTech Park, Nagpur, we often advise SMEs to begin their digital transformation journey by identifying exactly these small inefficiencies — because fixing them creates immediate impact.

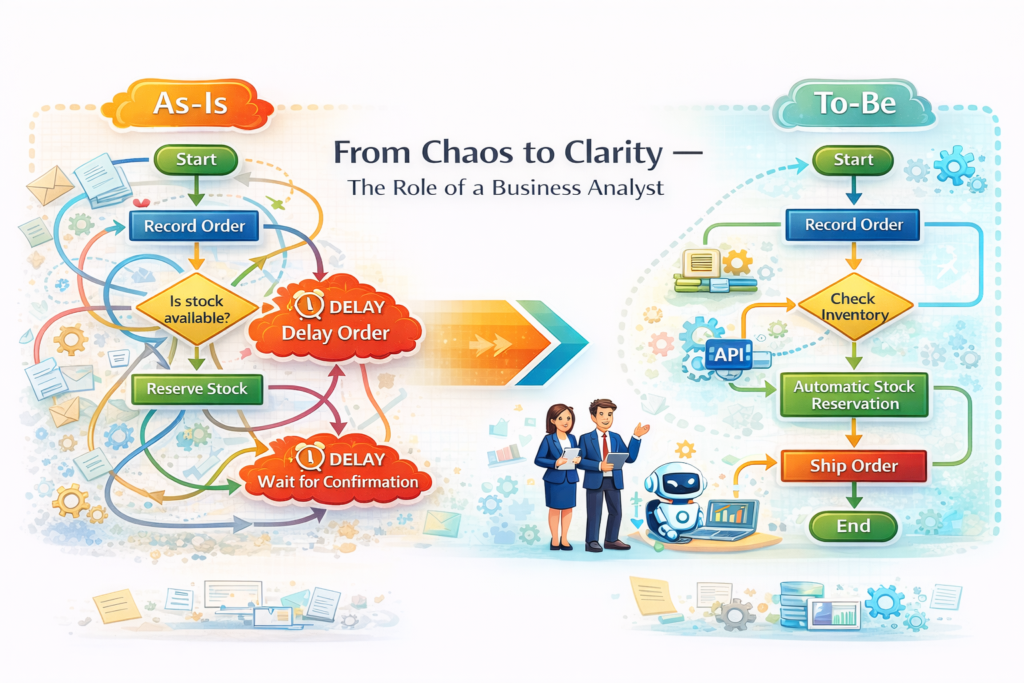

4. Proposing the Improved State (“To-Be” Process)

Improved Process Steps

- Customer places order through an online platform or mobile app.

- System auto-updates order in centralized database.

- Inventory check occurs in real-time via software integration.

- If stock is low, automatic supplier request is triggered.

- Delivery partner is assigned automatically.

- Multiple payment options offered (UPI, cards, wallets).

- Customer gets tracking notifications

5. Tools & Frameworks Applied

- BPMN Modeling for “To-Be” process.

- Gap Analysis Framework – To compare existing vs improved process.

- Feasibility Study – Ensures proposed improvements are cost-effective.

Table: Before vs After Improvements

| Aspect | Current Process (As-Is) | Improved Process (To-Be) |

| Order Recording | Manual ledger entry | Automated online system |

| Inventory Management | Physical stock check | Real-time integration with suppliers |

| Delivery | Manual arrangement | Automated partner assignment |

| Payments | Cash on Delivery only | Multiple digital options |

| Customer Experience | Delays, cancellations | Faster, transparent, trackable |

6. Hands-On Project Framework for Readers

To practice on your own:

- Choose a Process – It could be in your office, college, or even a daily routine (e.g., how your team schedules meetings).

- Document As-Is – Use flowcharts or simple sketches.

- Analyze Inefficiencies – Ask: What takes too long? What creates errors?

- Propose To-Be – Suggest improvements (digital tools, automation, new workflows).

- Validate Feasibility – Check costs, risks, and expected benefits.

- Present Your Findings – Create a table, model, or presentation.

At CuriosityTech (Phone: +91-9860555369, Email: contact@curiositytech.in), we ask interns to do exactly this as their first exercise — because process analysis builds confidence and gives real-world perspective.

7. Humanized Insight

When I was a junior analyst two decades ago, my first project was documenting a library book issuance process. I spent hours following librarians, only to discover most delays came from a single handwritten ledger. Replacing it with a simple Excel sheet reduced waiting times drastically. That experience shaped my belief: even small improvements can create big results.

And this is the spirit we bring to every learner at CuriosityTech — whether through our classroom training at 1st Floor, Plot No 81, Wardha Rd, Gajanan Nagar, Nagpur or our online programs.

8. Visual Abstract (Description)

- Left side: A cluttered “As-Is” process diagram showing manual steps, bottlenecks, and loops.

- Right side: A clean “To-Be” process diagram showing automation, integration, and faster flow.

- Center caption: “From Chaos to Clarity — The Role of a Business Analyst.”

Conclusion

Analyzing and improving a business process is not just about diagrams or tools—it’s about creating value, efficiency, and customer satisfaction. With hands-on practice, even beginners can spot inefficiencies and propose improvements that transform organizations.

In 2025 and beyond, the most successful business analysts will be those who can bridge the gap between theory and practice. By taking on small projects like this and gradually scaling up, you’ll gain the expertise to handle enterprise-level transformations.

If you’re ready to test these skills, CuriosityTech (Instagram: curiositytechpark, LinkedIn: Curiosity Tech, Facebook: Curiosity Tech) provides a collaborative platform to work on real projects with guided mentorship.